Competence

KTS understands itself as a technology business for development (hard-/software) and production of electronic controllers for gears, hydraulic drive units as well as fuel cells. We focus on supplying custom-made systems developed according to the customers´ specifications. Due to our long-term activities in the field of motive power-engineering, our company employs a permanent staff of highly qualified experts with a wide range of project experience. The flexible structure of our company enables us to carry out new or adaptive developments within the shortest periods of time. What is more, we are independent (i.e. there are no interconnections in capital with other companies) and can guarantee to our customers a full protection of know-how for their developments and projects.

We develop in compliance with the DIN ISO 9001, the V-model or the international safety standard IEC 61508.

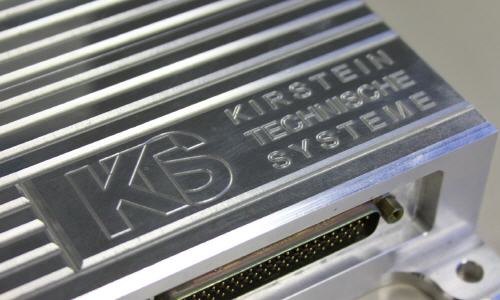

The microprocessored controllers have highly developed diagnosis functions, end-of-line programming and routine functions for internal error diagnosis. All controllers are extremely compact and have proved to function under the most difficult environmental conditions. Control systems with electronic engine intervention (e.g. EDC) or systems integrated in data bus systems (e.g. CAN) have been in operation successfully for many years.

KTS controllers are operated in automatic gears, automatized gear boxes, planetary gears, infinitely variable change-speed gears and in hydraulic drive units. Additionally, our controllers are in operation in mobile and stationary applications in fuel cell technology. Typical fields of applications are utility and passenger vehicles, buses, building machines, ocean-going ships, various stationary applications etc.

Our range of products also includes electro-mechanic operating components for motive power engineering, e.g. gear selectors, cablings, data recorders.

Depending on the installed sensor technology, our data recorders can record and memorize operational data over long periods of time (e.g. working temperatures, gear shifts, revs/min, engine torques, operating time). Of course, these data recorders are suited to operate under the harshest environmental conditions (vibration, dust, moisture, heat). Especially in development projects, functional drive tests or in oversea applications the data recorders have proved to be highly efficient.

Together with our partners we would like to point out the importance of innovations and high-tech for our future.